Skärlinjaler/Skärapparater från Keencut

Här är ett urval av Skärlinjaler/Skärapparater från Keencut som du hittar hos oss:

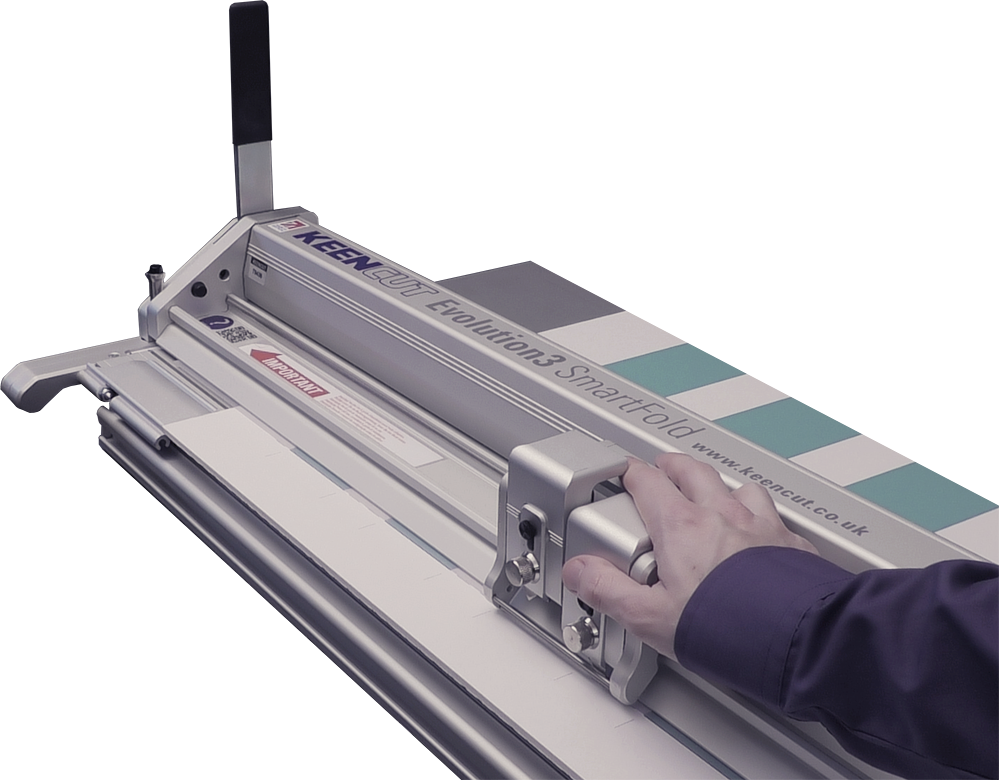

Evolution3 SmartFold

Designed for the busiest production facility, the Evolution3 SmartFold includes all the superior features of the Evolution3 range with the addition of an integral cutting strip for textiles and fragile materials.

The SmartFold can be folded down to clear the bench and then returned in seconds to be immediately ready for use.

Keencut’s unique Lift-and-Hover (patent pending) technology enables fast single-handed, and accurate alignment of all material, irrespective of thickness. Lower the clamping bar until it hovers just above the material surface with zero sag, even on the longest 5.5m (216″) length cutter, then use the sightline strip to see where the cut will be made, and finally, fully engage the clamp and cut – it’s so simple.

Single-handed, fast accurate alignment

Two unique features enable single-handed, fast and accurate alignment of all materials irrespective of thickness. The Lift-and-Hover system enables the clamping bar to be easily raised and then lowered so it hovers just above the material surface. The anti-sag mechanism means the cutter bar can be suspended exactly parallel to the media surface over the whole length of the cut with zero sag, even on the longest sized cutter.

Guaranteed accuracy

The Evolution3 is the most accurate cutter of its type on the market and is guaranteed to cut within 0.2mm (0.008″) of a straight line for the full length of the cut. The in-built ultra-high precision accuracy, combined with the perfect alignment made possible using the sightline strip, means every butt-jointed panel will join seamlessly. This ultra-high precision accuracy will save you time and money with less waste and fewer mistakes.

Total stability

The self-adjusting track roller system fitted to the QuikSwap tool heads provides a strong and smooth movement up and down the length of the cutter bar, with zero sideways movement to ensure a perfect straight line. This, coupled with rigid blade clamping, gives perfect blade control and spot-on accuracy, so less wastage and mistakes.

QuikSwap Double Graphik tool head

The Evolution3 Double Graphik tool head comes as standard and has two individual blade holders for two-way cutting. The blades are stronger and more stable than regular blades making the Double Graphik tool ideal for vinyl, banner, cardboard, PVC foamboard up to 13mm (1/2″), foam-centred board, corrugated plastic, paper, pop-up and roll-up materials.

Finns i storlekarna 1,1m, 1,6m, 2,1m, 2,6m, 3,1m & 3,6m.

Fler produkter finner du på www.Keencut.com

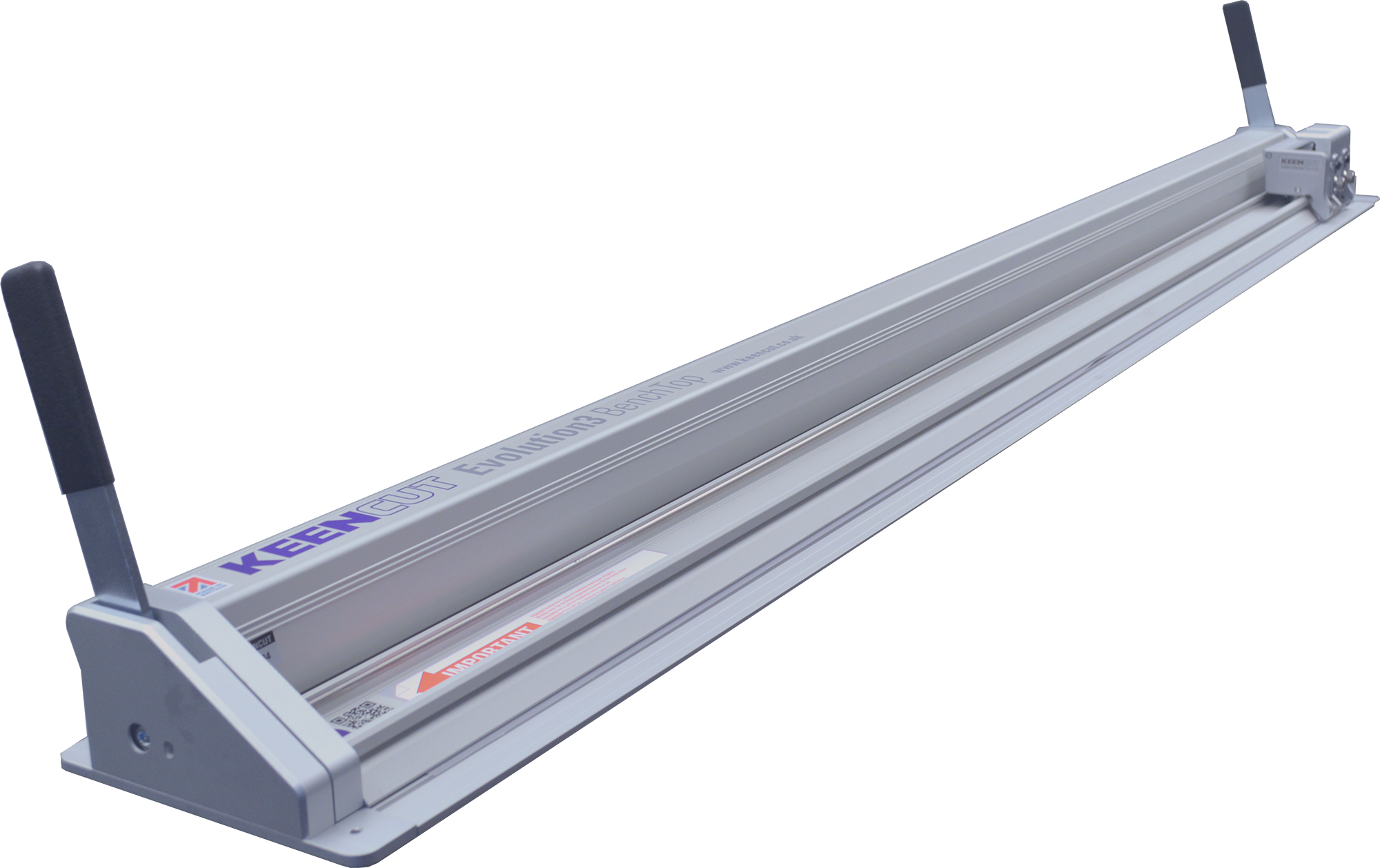

Evolution3 BenchTop

Permanently installed for immediate use, the Evolution3 BenchTop is perfect for a busy studio or high use production environment.

Keencut’s unique Lift-and-Hover (patent pending) technology enables single-handed, fast and accurate alignment of all material, irrespective of thickness. Lower the clamping bar and it hovers just above the material surface with zero sag, even on the full length 5.5m (216″) cutter. Use the sightline strip to see where the cut will be made, then fully engage the clamp – it’s so simple.

You can rapidly change the QuikSwap heads to provide general cutting, creasing or fabric cutting, and you are always guaranteed ultra-high 0.2mm (0.008″) precision accuracy with every cut.

Single handed operation

Two unique, patent pending features enable single-handed, fast and accurate alignment of all materials, irrespective of thickness. The Lift-and-Hover system enables the clamping bar to be easily raised and then lowered so it hovers just above the material surface. The anti-sag mechanism means the cutter bar can be suspended exactly parallel to the media surface over the whole length of the cut with zero sag.

The self-adjusting track roller system fitted to the QuikSwap tool heads provides a strong and smooth movement up and down the length of the cutter bar, with zero sideways movement to ensure a perfect straight line. This, coupled with rigid blade clamping, gives perfect blade control and spot-on accuracy, so less wastage and mistakes.

Total stability

The self-adjusting track roller system fitted to the QuikSwap tool heads provides a strong and smooth movement up and down the length of the cutter bar, with zero sideways movement to ensure a perfect straight line. This, coupled with rigid blade clamping, gives perfect blade control and spot-on accuracy, so less wastage and mistakes.

QuikSwap Double Graphik tool head

The Evolution3 Double Graphik tool head comes as standard and has two individual blade holders for two-way cutting. The blades are stronger and more stable than regular blades making the Double Graphik tool ideal for vinyl, banner, cardboard, PVC foamboard up to 13mm (1/2″), foam-centred board, corrugated plastic, paper, pop-up and roll-up materials.

Finns i storlekarna 1,1m, 1,6m, 2,1m, 2,6m, 3,1m & 3,6m.

Fler produkter finner du på www.Keencut.com

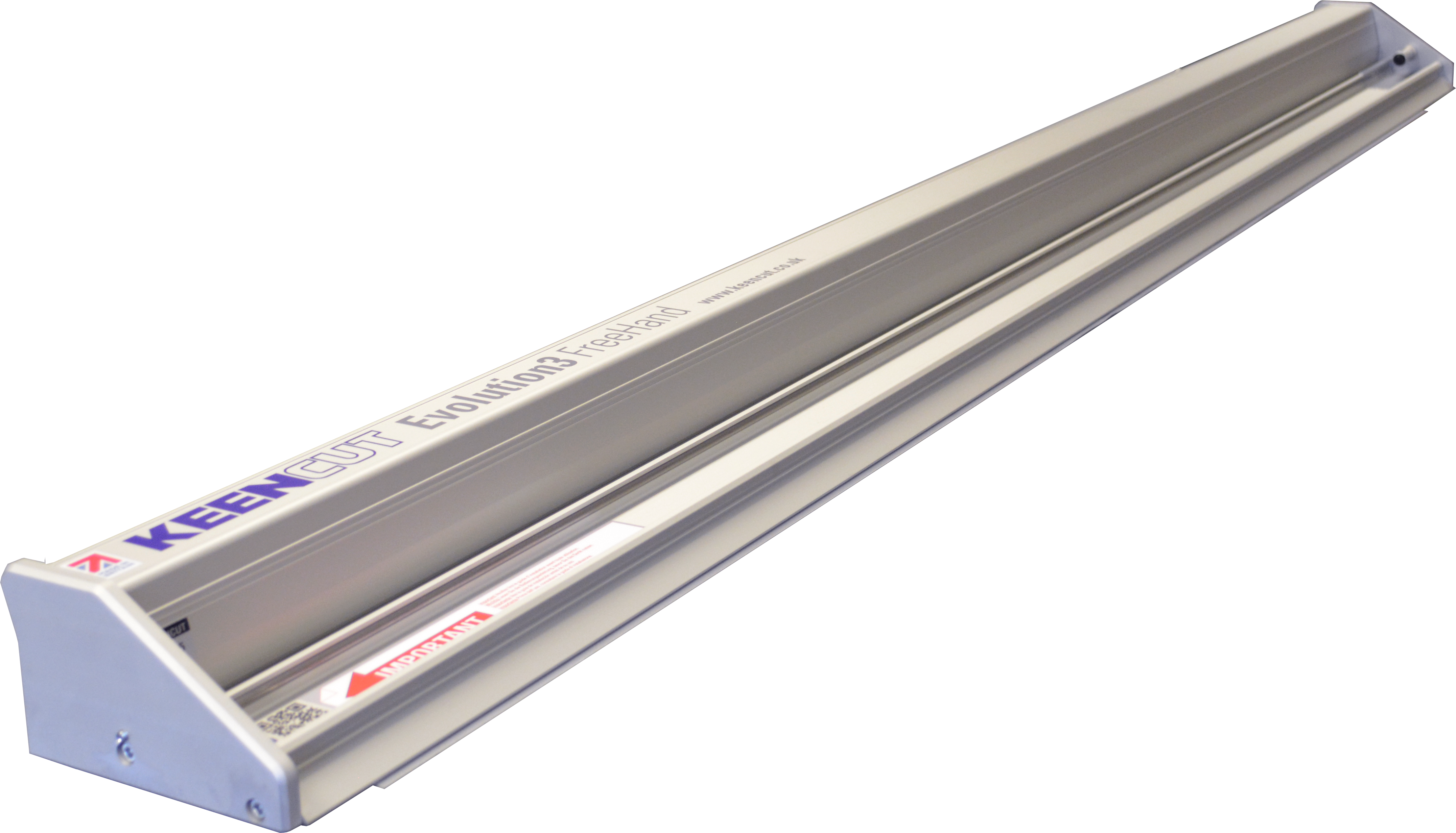

Evolution3 FreeHand

The Evolution3 FreeHand has been designed for those who require the high precision accuracy and superior cutting quality of the Evolution3 range but in a more flexible format.

It is perfect for a workshop where the cutter bar is required to move between workbenches.

Evolution3 FreeHand gives you all the benefits of the QuikSwap cutting tools, sightline strip accuracy and anti-sag design in a portable cutter.

Guaranteed accuracy

The Evolution3 is the most accurate cutter of its type on the market and is guaranteed to cut within 0.2mm (0.008″) of a straight line for the length of the cut. The in-built ultra-precision accuracy combined with the perfect alignment, made possible using the sightline strip, means every butt-jointed panel will join seamlessly. This ultra-precision accuracy will save you time and money with less waste and fewer mistakes.

Total stability

The self-adjusting track roller system fitted to the QuikSwap tool heads provides a strong and smooth movement up and down the length of the cutter bar, with zero sideways movement to ensure a perfect straight line. This, coupled with rigid blade clamping gives perfect blade control and spot-on accuracy, so less wastage and mistakes. On the FreeHand, the underside of the cutter bar has two silicone strips that will grip to the material surface preventing any chance of it slipping.

Heavy duty reliability

The entire Evolution3 range has been built to last using high quality materials and well tested engineering principles. The cutting head bearing system guarantees perfect blade control even with the most difficult of materials. Keencut make the majority of components on its high-tech CNC machines keeping tolerances and quality under constant control, this assures exceptional accuracy and total reliability.

QuikSwap Double Graphik tool head

The Evolution3 Double Graphik tool head comes as standard and has two individual blade holders for two-way cutting. The blades are stronger and more stable than regular blades making the Double Graphik tool ideal for vinyl, banner, cardboard, PVC foamboard up to 13mm (1/2″), foam-centred board, corrugated plastic, paper, pop-up and roll-up materials.

Finns i storlekarna 1,1m, 1,6m, 2,1m, 2,6m & 3,1m.

Fler produkter finner du på www.Keencut.com

Sabre Series 2

Keencut’s Sabre Series 2 is an out of the box ready to use solution for medium-volume cutting. It’s perfect for the print shop, workshop, studio, architects’ practice, or educational institutions. The Sabre combines Keencut safety with versatile general-purpose cutting; it does not need to be fixed to a dedicated bench, and there is no set-up.

The Sabre provides a straight square cut of materials from 13mm (1/2″) thick foamboard to delicate tissue paper. Floating, self-adjusting hinges automatically adapt for stable lay-flat cutting and offer the opportunity to cut wider sheet materials.

Space-saving and fully mobile, the Sabre can be mounted on an optional stand and fitted with a waste catcher and roll feed. The safety features make it ideally suited for use by inexperienced operators in any environment.

Simple to use

The Sabre Series 2 is simple to operate, requiring little training. The ergonomically designed cutting head allows single-handed cutting action and uses downward pressure to engage the blade. The single tool head offers a choice of three blade holders which can be switched safely and quickly to suit different materials. Blade changing and depth adjustment are simple and completed without the use of additional tools.2

The Sabre Series 2 has three blades as standard:

Graphik blade holder: designed for the sign maker and digital printer with a specially crafted knife edge for extra stability in tougher materials and a cutting depth of up to 13mm (1/2″). By running the blade backwards, acrylics can be scored for snapping. The reversible blades have the ability to be set to cut left-right or right-left.

Rotary blade holder: cold cuts textiles and other delicate materials and is ideal for trimming thin strips off banners and posters where a knife blade would be too aggressive. It is fitted with a red safety blade guard to be engaged when not in use. A cutting mat is required to be used when using the rotary blade holder, please note this is not supplied.

Medium duty blade holder: uses standard off-the-shelf medium duty utility blades for general purpose, economical cutting and can be adjusted to cut materials up to a depth of 10mm (3/8″).

Fler produkter finner du på www.Keencut.com

Finns i storlekarna 1,0m, 1,5m, 2,0m, 2,5m & 3,0m

Simplex

The lightweight, portable cutter

Remove the safety risk of using a hand knife by adding the lightweight Keencut Simplex to your tool kit. Ideal in the workshop or on-site, the Simplex offers safe, straight cutting in any environment.

For optimum workflow in the busy workshop, combine the Keencut Simplex and the Keencut Evolution3™. The Simplex provides non-fixed flexible straight-line cutting leaving the Evolution3™ to tackle high volume, high accuracy tasks.

The Simplex is very adaptable, providing the safe, accurate cutting of a wide variety of semi-rigid and flexible materials up to 3.1 metres (124″) wide, with a cutting depth of up to 10mm (3/8″) depending on the material.

Built to be portable

The Simplex is lightweight and robust and can withstand the rigours of on-site working whilst being truly portable. By manufacturing in-house, with only the highest quality materials, Keencut can guarantee that the Simplex will provide reliable long-lasting and accurate service. The Simplex also has a comprehensive five year guarantee.

The versatile cutter

The Simplex is very adaptable providing the safe, accurate cutting of a wide variety of rigid, semi-rigid and flexible materials up to 3.1 metres (124″) wide. The utility blades will cut to a depth of 10mm (3/8″). By adding the optional textile cutter, the material range of the Simplex is extended to delicate materials. There are 5 Simplex model sizes to choose from and a cutting mat is required for safe operation. Please note, the cutting mat is not supplied.

Finns i storlekarna 1,1m, 1,6m, 2,1m, 2,6m & 3,1m.

Fler produkter finner du på www.Keencut.com

SteelTrak

The Keencut SteelTrak cuts and finishes in one movement leaving materials safe to touch – there’s no dust and no scrapings. It increases production speed ensuring perfect accuracy, finishing quality, and safety.

SteelTrak is a high production machine for cutting rigid and semi-rigid materials and scoring and snaping glass and acrylic. It’s ideal for cutting or v-grooving Aluminium Composite, with a fast set-up for cutting identical boards. Cutting takes minimal effort and only a few minutes of training.

With a SteelTrak, you can buy larger cost-effective boards, reduce waste, and increase quality and productivity.

Cut steel and aluminium composite safely and accurately

The newly developed SteelTrak C2 composite cutting head will cut steel composite panel, e.g Multishield and aluminium composite panel, e.g DiBond, in a single pass without creating dangerous sparks or dust. The new cutting head significantly reduces any curvature on the cut material to facilitate successful flat-bed printing and minimise waste. There is no need for extra edge finishing, so productivity is increased, and safety guaranteed.

Note: The SteelTrak is now supplied with the new SteelTrak C2 composite cutting head as standard. Existing SteelTrak users can purchase an upgrade from their Keencut dealer.

Finns i storlekarna 1,65m, 2,10m, 2,50m.

Fler produkter finner du på www.Keencut.com

Excalibur 3S

The Excalibur 3S is a premium cutting machine with exceptional return on investment. It is ideal for those who do not need the heavy production features of the SteelTrak.

The Excalibur 3S is suited to the regular cutting of light and medium-weight boards and can also cut tough materials including 3mm (3/32″) aluminium composite panels.

Simple alignment and permanently mounted blades guarantee a fast and accurate finish. Its unique features will allow you to improve quality, reduce waste and increase productivity.

Perfect cuts

Accuracy is assured with a clear sightline strip acting as your guide to precise alignment. A one-piece horizontal squaring arm ensures positioning and rigidity either side of the cut line. Once aligned, materials are held firmly by a unique pressure-sensitive clamp, which is designed to protect delicate surfaces from damage.

Versatile cutter

The Excalibur 3S will cut a wide variety of materials. The twin wheel cutter will tackle tougher materials including aluminium composite panels, e.g DiBond and MDF up to 3mm (3/32″), producing a clean, safe edge in a single pass.

Fler produkter finner du på www.Keencut.com

Ultimat Futura

The Ultimat Futura is the easiest to use precision mountboard cutter on the market.

With unequalled blade control and micro-stop calibration, you are assured of complete accuracy. You will create a perfect mount bevel and exact corners without over or undercutting, every time.

The smooth sliding action requires minimum effort, even when you are cutting through 8 ply mount board.

With the Ultimat Futura you can easily switch between different types of board and thicknesses, in seconds.

Consistent faultless mounts

The Ultimat Futura performs perfectly on even the thickest conservation mountboard. The blade cartridge system provides accurate blade depth control and a measuring stop ensures flawless v-grooves. Everything is squared and calibrated ready for you to use straight out of the box.

No more overcuts or undercuts

The micro stop adjusters fitted to the start of cut, end of cut and margin guide stops, allow you to dial out overcuts or undercuts in seconds. It’s so simple, any overcut is eliminated by turning the stop thumbscrew towards minus (-) and any undercut is eliminated by turning the thumbscrew towards plus (+). A rigid self-aligning margin guide ensures consistent accurate parallel borders.

Unequalled blade control and effortless cutting

The Ultimat Futura cutting head has built-in self-adjusting ball bearing rollers operating on twin stainless-steel tracks, to deliver a sliding action that is smooth, precise and with no discernible friction. The blade holders are mounted on large thrust and radial bearings for precision blade control with zero side-play. The heavy-duty, one-piece aluminium extruded base gives absolute stability. Maximum operator effort is transmitted to the blade, to allow easy cutting of even the thickest boards.

Finns i storlekarna 1,0m, 1,2m, 1,5m.

Fler produkter finner du på www.Keencut.com